For many retired engineers, the search for a new passion project doesn’t end at retirement—it simply shifts gears. The same curiosity, precision, and love for systems that once drove them to design machines or solve complex problems now lead them toward hands-on hobbies and practical innovations at home. One surprising favorite among this group? The Stay Fresh Freeze Dryer – a machine that combines technical craftsmanship, long-term value, and a touch of scientific fascination.

A Machine Built for Those Who Appreciate Engineering

Retired engineers have a knack for recognizing solid design. They know when a product is made to last versus when it’s made to look good on paper. That’s why the Stay Fresh Freeze Dryer has become a quiet favorite—it isn’t just a home appliance; it’s an industrial-grade system scaled down for personal use.

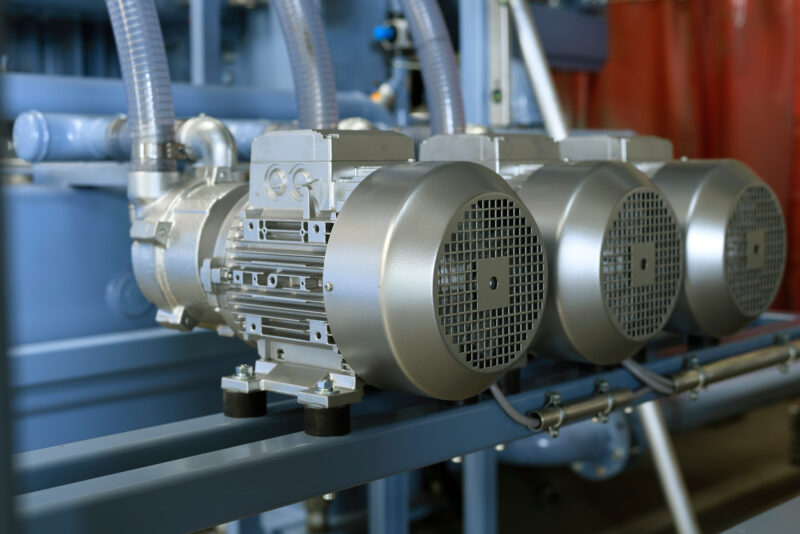

The entire unit is crafted with 304 stainless-steel piping, a motorized ball valve, and an industrial vacuum pump—features that most consumer-grade freeze dryers simply don’t have. These are the same materials and design principles found in commercial lab equipment or industrial food preservation systems.

Many retired engineers love that they can see the logic of the system. The vacuum chamber, sensors, refrigeration cycle, and control logic all operate in harmony, demonstrating elegant engineering in action. It’s not just about making freeze-dried food—it’s about understanding the process of sublimation, heat transfer, and vacuum control, right there in their garage or workshop.

Turning Engineering Curiosity into Culinary Creativity

After years in the workforce, most engineers crave projects that are both practical and fun. Freeze-drying satisfies both urges. It’s science that you can eat.

With the Stay Fresh Freeze Dryer, they can experiment with fruits, vegetables, meats, and even full meals. Some treat it like a personal R&D lab—tracking temperature curves, adjusting drying cycles, and logging results just like they did in their careers. Others simply enjoy the convenience of producing their own lightweight, long-lasting food for camping, hiking, or emergency preparedness.

Freeze-drying preserves up to 97% of the original nutrients, flavor, and color, making it an elegant solution for anyone who values precision and efficiency. Engineers appreciate optimization, and there’s something deeply satisfying about creating food that can last for years without preservatives—all while retaining its integrity.

The Engineering Marvel Behind the Stay Fresh System

Unlike typical home freeze-dryers, the Stay Fresh system uses a powerful industrial vacuum pump and a smart control interface that automatically manages temperature, pressure, and drying time. It’s not a simple timer-based appliance – it’s a dynamic process controller.

Many engineers are impressed by how closely the system mimics the freeze-drying processes used in pharmaceuticals and aerospace food preparation. The machine cools food rapidly to subzero temperatures, applies controlled vacuum pressure to remove moisture through sublimation, and then slowly warms the product for a perfect dry finish. Every phase is calculated and measurable – precisely the kind of system an engineer can admire.

Built to Last, Designed to Impress

Durability is another major reason engineers gravitate toward Stay Fresh. These machines are designed for longevity, not just aesthetics. The heavy-duty stainless-steel chamber resists corrosion, the vacuum system uses industrial-grade seals, and the entire unit is built with easy access for maintenance.

It’s not a disposable appliance; it’s a long-term investment. Many Stay Fresh owners treat their dryers like they would a classic piece of equipment—cleaning, calibrating, and maintaining them for years of use. Engineers, in particular, value that sense of mechanical stewardship.

Moreover, Stay Fresh dryers are quiet, efficient, and energy-optimized. The compressor and pump systems have been tuned to balance throughput with low power draw, ensuring high performance without the noise and energy waste often associated with consumer-level freeze dryers.

The Perfect Post-Retirement Project

Retirement often gives people time to explore passions they never had time for before. For engineers, freeze-drying can easily turn into an engaging and educational hobby. It offers endless opportunities for experimentation – testing cycle times, comparing batch performance, even engineering custom trays or accessories.

Some retirees use their Stay Fresh dryers to preserve family recipes, creating freeze-dried meals their children and grandchildren can enjoy for years. Others build small side businesses, selling freeze-dried candy, fruit snacks, or emergency food kits at local markets.

One retired electrical engineer from Oregon described his experience:

“I bought a Stay Fresh Freeze Dryer out of curiosity. Now it’s become my favorite machine in the house. It’s beautifully built, easy to maintain, and it runs like clockwork. I’ve used it to preserve strawberries, eggs, and even lasagna. My wife jokes that it’s my new engineering project—except this one feeds the family.”

Why Engineers Choose Stay Fresh Over Other Brands

When comparing Stay Fresh to competitors like Harvest Right or Blue Alpine, many technically minded users highlight key differences. Stay Fresh dryers use industrial-grade components rather than consumer-grade substitutes. The vacuum pump is larger and more robust, the piping is stainless rather than plastic, and the automated defrost and valve systems are powered rather than manual.

Engineers appreciate this attention to detail. They see it as a machine designed by engineers, for engineers—a unit that prioritizes reliability, efficiency, and maintainability over marketing gimmicks.

Moreover, Stay Fresh Technology backs its products with responsive customer support and transparent technical documentation. That’s something engineers particularly value—they like to understand how things work, and Stay Fresh provides the diagrams, manuals, and support to make that possible.

Practical Benefits Beyond the Workshop

Of course, the appeal of the Stay Fresh Freeze Dryer extends beyond its technical charm. The practical benefits are enormous. Owners save money by buying food in bulk and preserving it themselves. They gain independence by reducing waste and ensuring they always have healthy food available, even in uncertain times.

For retired professionals who value self-sufficiency and preparedness, that’s empowering. Many also enjoy sharing their creations with friends and neighbors—freeze-dried ice cream, crispy fruit snacks, or savory meals that rehydrate beautifully. It becomes both a science project and a way to give back to the community.

A Tool for the Mind and the Future

In a way, the Stay Fresh Freeze Dryer represents the perfect intersection of technology, sustainability, and curiosity—the same values that defined many engineers’ careers. It’s a tool that encourages problem-solving, hands-on learning, and continual improvement.

Even in retirement, those instincts don’t fade. Whether they’re optimizing drying cycles, experimenting with different food textures, or fine-tuning the vacuum pump, retired engineers find in Stay Fresh a sense of purpose that feels both familiar and exciting.

Conclusion

For those who spent their careers building systems, designing machinery, or improving processes, the Stay Fresh Freeze Dryer offers a new kind of satisfaction. It’s a chance to apply that same analytical mind to something tangible, useful, and surprisingly fun.

Stay Fresh isn’t just another appliance—it’s a precision instrument that invites exploration, rewards curiosity, and delivers real-world results. For many retired engineers, that makes it not just a favorite gadget—but a symbol of lifelong learning and innovation.